Our Services

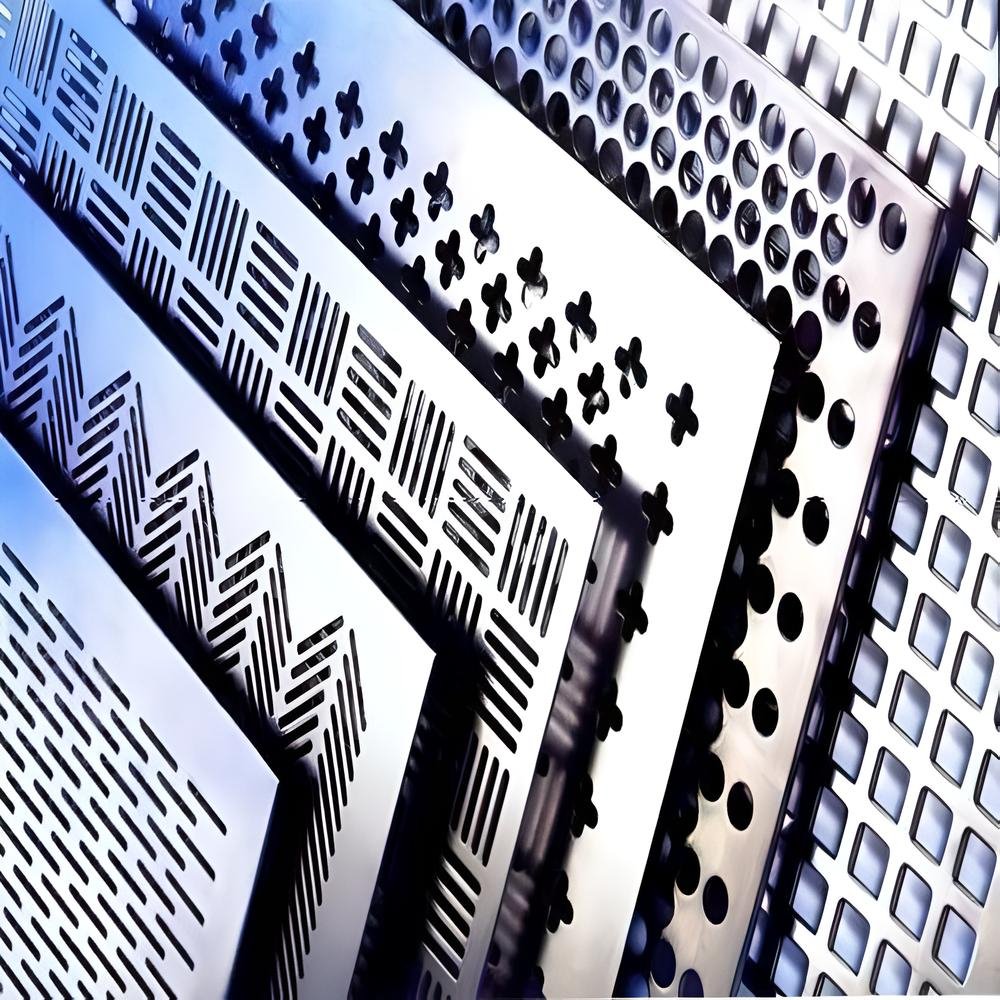

At Metall Holz, we specialize in precision Sheet Metal Laser Cutting, offering exceptional quality and accuracy for a wide range of materials. Leveraging advanced fiber laser cutting technology, we ensure high-speed, high-precision results suitable for diverse industrial and commercial applications.

Key Features:

- Unmatched precision: Our state-of-the-art laser cutting systems deliver intricate designs and sharp edges with unparalleled accuracy, ensuring minimal material wastage.

- Versatile material handling: We cut a variety of materials, including Mild Steel, Stainless Steel, Aluminum, Copper, Brass and other Alloy Metals.

- Customizable Solutions: From prototypes to large-scale production runs, we tailor our services to meet your exact specifications and requirements.

- Efficiency and Speed: Automated systems integrated into our laser cutters enhance production speed while maintaining consistent quality, ensuring quick turnaround times for your projects.

- Cost-Effective Manufacturing: Our advanced processes reduce operational costs without compromising on quality, providing you with a competitive edge.

Let us bring your ideas to life with our superior Sheet Metal Laser Cutting Services. Contact METALL HOLZ today to discuss your project requirements!

At METALL HOLZ, we offer precision Laser Metal Plate Cutting Services tailored to meet the diverse needs of industries requiring high-quality metal components. Our advanced laser cutting technology ensures accurate, efficient, and cost-effective solutions for metal plates of varying thicknesses and materials.

Key Features:

- High Precision: Laser technology provides exceptional accuracy, producing clean and sharp cuts with minimal distortion, even on thick plates.

- Versatile material handling: We cut a variety of materials, including Mild Steel, Stainless Steel, Aluminum, Copper, Brass and other Alloy Metals.

- Cutting Capacity: Capable of cutting metal plates with thicknesses up to:

- Mild Steel: 40 mm

- Stainless Steel: 35 mm

- Aluminum: 35 mm

- Copper & Brass: 20 mm

- Large Plate Handling: Our machine can accommodate large plate sizes, such as 4000 mm x 2000 mm, ensuring flexibility for various applications.

- Advanced Technology: High-powered fiber laser systems ensure fast and efficient cutting, ideal for both intricate designs and large-scale projects.

Let us bring your designs to life with the precision and quality of our Laser Metal Plate Cutting Services. Contact METALL HOLZ today to discuss your project requirements!

At METALL HOLZ, we offer advanced Fiber Laser Cutting Services specifically designed for metal tubes and profiles. Equipped with state-of-the-art machinery and a skilled team, we deliver precision cuts that meet the highest industry standards, ensuring unmatched quality and efficiency.

Key Features:

- Cutting Capacity:

- Tube Length: Up to 350 mm diameter and 6000 mm length

- Round Tube: 10 mm – 300 mm diameter

- Square Tube: Up to 150 mm x 150 mm

- Wall Thickness: 1 mm – 8 mm

- Supported Profiles: Round, Square, Rectangle, Oval, Tubes, Angles, C-Channel, I-Beam, and more.

- Precision Cutting: Achieve intricate designs and detailed patterns with accuracy.

- Material Versatility: Suitable for a wide range of metals, including:

- Mild Steel (MS): Up to 12 mm

- Stainless Steel (SS): Up to 8 mm

- Aluminum: Up to 6 mm

- Copper & Brass: Up to 20 mm

- Other Alloy Metals

- Customizable Shapes: Expertise in cutting Round, Square, Rectangular, and other tube profiles to your specifications.

- High-Speed Production: We ensure rapid turnaround times for projects of all sizes, delivering quality results without delays.

Let us transform your designs into reality with our Fiber Tube Metal Cutting Services. Contact METALL HOLZ today to discuss your project requirements!

At Metall Holz, we specialize in Custom Laser Cutting Services, using advanced fiber laser technology to deliver fast, precise, and clean cuts on a wide range of materials. This high-precision process creates intricate shapes and designs while minimizing the need for additional finishing, ensuring exceptional results tailored to your project needs.

Key Features:

- Exceptional Precision: Our fiber laser cutting technology ensures accurate and detailed cuts, perfect for even the most complex designs.

- Wide Range of Materials: We can cut a variety of metals, including Mild Steel, Stainless Steel, Aluminum, Brass, Copper, and other Alloy Metals. Whether you need thin sheets or medium-thickness metals, we have the right tools to get the job done.

- High-Speed Processing: Our fiber laser cutting machines operate at high speeds, allowing us to deliver your projects quickly without compromising on quality. This is especially beneficial for high-volume or time-sensitive orders.

- Clean Cuts with Minimal Waste: The focused laser beam ensures that the cutting process is efficient, producing minimal material waste and providing clean, sharp edges that often require no additional finishing.

- Cost-Effective Solutions: Fiber laser cutting reduces the need for expensive tools and minimizes material waste, allowing us to offer competitive pricing for both small and large projects.

- Versatile Design Capabilities: From simple geometries to intricate patterns, our CNC-controlled systems can handle designs of any complexity, including logos, text, and custom artwork.

Whether you need a single custom piece or a high-volume production run, Metall Holz is your trusted partner for custom laser cutting services. Contact us today to discuss your project, get a quote, or learn more about how we can help bring your ideas to life.

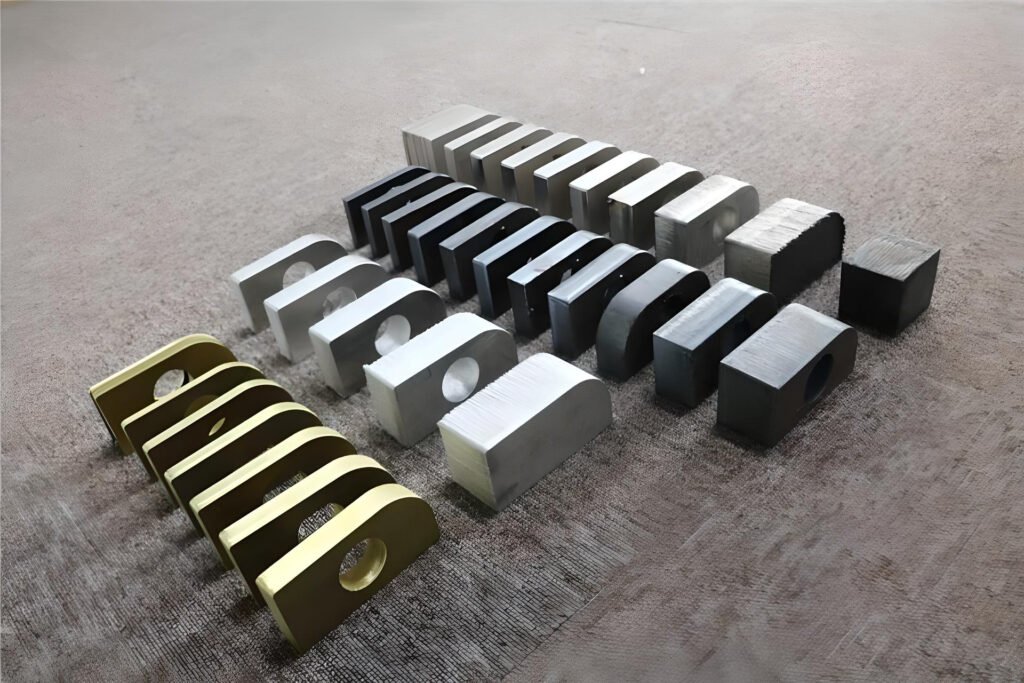

At Metall Holz, we deliver precision cutting services with unmatched accuracy and quality. Leveraging advanced laser cutting, CNC machining, and fiber laser technology, we craft flawless metal components with exact cuts and intricate details. Precision is critical in industries where even the slightest deviation can lead to inefficiencies, and we ensure every project meets exact specifications.

Key Features:

- Unparalleled Accuracy: Achieves high-precision cuts with fine tolerances, perfect for intricate designs, tight fits, and complex geometries.

- State-of-the-Art Technology: Utilizes cutting-edge fiber laser and CNC machines for superior precision, high-quality finishes, and fast turnaround times

- Custom Solutions: Tailors processes for both small-batch and high-volume production, handling everything from simple shapes to intricate patterns.

- Versatile Material Capabilities: Works with Stainless Steel, Mild Steel, Aluminum, Brass, Copper, and more, cutting materials of varying thicknesses.

- Optimized Efficiency: Reduces material waste with advanced cutting processes, ensuring cost-effective and sustainable solutions

- Flawless Finishes: Delivers clean, smooth edges with minimal burrs, reducing or eliminating the need for post-processing.

If you need precision cutting for your next project, Metall Holz is ready to deliver superior quality with exacting standards. Contact us today for a quote or to discuss your project in detail.

At Metall Holz, we offer precise and efficient sheet metal bending solutions tailored to meet your unique requirements. By utilizing our state-of-the-art bending machines, we ensure high-quality results with unmatched precision and consistency.

Key Features

- Precision Bending: Delivering accurate angles and consistent bends to ensure the final product perfectly aligns with your design specifications.

- Versatile Material Compatibility: We expertly handle a wide range of materials, including Mild Steel, Stainless Steel, Aluminum, Brass, and Copper, catering to diverse applications.

- Custom Shaping: From simple to intricate designs, we specialize in creating complex bends and shapes that balance form and function.

- High Efficiency: Our advanced technology guarantees fast turnaround times without compromising quality, making us ideal for both small-scale batches and high-volume production runs.

- Cost-Effective Solutions: By leveraging our expertise and cutting-edge equipment, we deliver affordable services while maintaining the highest standards of quality and precision.

Our Sheet Metal Bending Service is engineered to provide superior accuracy, flexibility, and cost-efficiency. Whether you’re working on a prototype or a large-scale production project, we are committed to exceeding your expectations with reliable and innovative bending solutions. Contact Metall Holz today to discuss your project requirements.

At Metall Holz, we specialize in high-precision Fabrication and Welding Solutions, utilizing advanced techniques to deliver strong, clean, and durable results. Our expertise in Laser Cutting, TIG, MIG, and Arc Welding allows us to choose the ideal method for each project—whether it requires intricate detailing, seamless precision, or heavy-duty structural strength.

With a team of skilled professionals, we ensure precision, consistency, and superior craftsmanship, making our fabrication and welding services ideal for a wide range of industries, including Automotive, Aerospace, Construction, Electronics, and Industrial Manufacturing.

Key Features:

- Laser Cutting & Welding: A high-precision, clean, and efficient process with minimal heat distortion, perfect for delicate or intricate applications.

- TIG Welding: Delivers strong, precise, and aesthetically refined welds, perfect for thin materials and high-quality finishes.

- MIG Welding: A fast, efficient welding technique suitable for thicker materials and high-production environments.

- Arc Welding: A versatile and robust technique, commonly used for heavy-duty structural applications and outdoor projects.

- Custom Fabrication: Tailored metalwork solutions designed to meet specific project requirements, ensuring functionality, durability, and aesthetic appeal.

Looking for precision fabrication and welding solutions tailored to your project’s needs? Contact Metall Holz today to create strong, durable, and aesthetically refined structures. Let our expert craftsmanship and cutting-edge technology bring your vision to life!

Prototype Production is a crucial phase in the product development process, enabling manufacturers to validate product designs and ensure they meet the required specifications before moving to mass production. This process helps identify potential issues early, reduce risks, and fine-tune the design for efficient manufacturing.

Key Features:

- Design Validation: Ensures the product meets functional requirements, identifying design flaws or usability issues to align with customer expectations.

- Performance Testing: Verifies the product’s durability, safety, and efficiency, ensuring it performs as intended in real-world conditions.

- Material Selection & Feasibility: Assesses the suitability of materials and manufacturing processes to ensure cost-effectiveness and precision for mass production.

- Manufacturing Process Evaluation: Identifies potential challenges in tooling, assembly, and production, ensuring smooth scaling for mass production.

- Cost Estimation & Optimization: Offers accurate cost estimates and optimizes the design to reduce production costs while boosting efficiency.

- Consumer Feedback: Collects valuable insights to refine features and enhance the overall user experience.

- Risk Reduction: Identifies potential risks early, ensuring the product meets quality standards and is delivered on time.

At Metall Holz, we recognize the importance of Prototype Production in bringing your product vision to life. Whether you’re validating a new design, testing performance, or refining manufacturing processes, our team is here to assist you at every stage. Contact us today to discuss how we can streamline your product development and ensure your success in mass production.

At Metall Holz, we specialize in precision cutting across a diverse range of metals, including Mild Steel, Stainless Steel, Aluminum, Copper, Brass, and other Alloys. Whether it’s thin sheets, thick plates, or intricate tubes and profiles, our state-of-the-art sheet and tube laser cutting technology ensures exceptional accuracy, superior quality, and a flawless finish for every project.

Contact Metall Holz to find the best material solution tailored to your specific project requirements.